If you think about your home's HVAC system, the furnace and AC get all the attention. But the real workhorse? That's the ductwork. It’s like your home’s circulatory system, responsible for carrying conditioned air to every single room. A professional installation of ductwork isn't just a construction task; it's a carefully planned project that blends design, fabrication, and precise assembly to guarantee your home is comfortable and efficient for years to come.

What a Professional Ductwork Installation Involves

Getting new ductwork installed properly is about much more than just connecting a few pipes and vents. It’s a custom engineering job designed specifically for your home, and it starts long before anyone picks up a tool. The first step is a deep dive into your home's unique characteristics—its layout, insulation, window placement, and the specific power of your furnace and air conditioner.

This initial evaluation is everything. It provides the data technicians need to run critical calculations that determine the perfect size and configuration for your duct system. This isn't just a best guess; it's a science. The right calculations ensure every room gets the airflow it needs for consistent temperatures, all while preventing your expensive HVAC unit from working harder than it has to.

The Blueprint for Home Comfort

Once the design is locked in, the real work begins with fabrication and installation. This is where technicians build the main supply and return "trunk lines"—the superhighways of your HVAC system. From there, they run smaller "branch lines" out to individual rooms. A top-tier installation doesn't just slap pieces together; it considers integrated ductwork and ventilation strategies to ensure the entire system works in harmony.

A quality installation always focuses on these key details:

- Smart Layout Planning: Pros aim for the most direct path for air to travel. This means minimizing sharp bends and long, winding runs that slow down airflow and reduce efficiency.

- Airtight Connections: Every joint, seam, and connection is mechanically fastened and then completely sealed with industry-grade mastic or special foil tape. This is critical for preventing the air you paid to heat or cool from leaking into your walls.

- Proper Support: Ducts are hung securely with the right strapping to prevent them from sagging over time. A sagging duct can create kinks and bottlenecks that choke off airflow.

This level of detail is why skilled installers are in such high demand. Just to give you an idea, California alone had about 35,630 heating, air conditioning, and refrigeration pros employed as of May 2023, driven by a constant flow of new builds and system upgrades.

Think of a well-installed duct system as the unsung hero of your home's energy efficiency. It’s what makes sure the comfortable air you’re paying for actually gets to you, instead of getting lost in the attic or crawl space.

The job isn't finished until the system is tested and balanced. A true professional will measure the airflow coming out of every vent to confirm it matches the original design, making fine-tune adjustments as needed. It's also important for homeowners to recognize when their system is failing, which is why we put together a guide on the signs of an air duct system you shouldn't ignore.

To help you visualize the entire process, here’s a breakdown of the key stages involved.

Key Stages of a Professional Ductwork Installation

| Stage | Key Objective | Why It Matters |

|---|---|---|

| 1. Assessment & Design | To create a custom blueprint based on your home's heating/cooling load and layout. | A proper design ensures every room gets the right amount of air, preventing hot/cold spots and saving energy. |

| 2. Material Fabrication | To precisely cut and shape the sheet metal, ductboard, or flexible ducts to match the design. | Custom-fit components minimize leaks and airflow restrictions compared to ill-fitting, off-the-shelf parts. |

| 3. Installation & Assembly | To physically install the trunk lines, branch runs, and vents, ensuring proper support and connections. | A secure and well-supported system prevents sagging and noise while ensuring long-term durability. |

| 4. Sealing & Insulating | To seal every joint and seam with mastic or tape and wrap ducts in unconditioned spaces with insulation. | This is the most critical step for efficiency, stopping conditioned air from leaking out and saving you money. |

| 5. Testing & Balancing | To measure airflow at each register and adjust dampers to ensure the system performs as designed. | Balancing guarantees consistent comfort throughout the house and confirms the system is delivering what it promised. |

Following these steps methodically is what separates a quick, cheap job from a professional installation that delivers lasting comfort and value.

Choosing the Right Materials for Your Ductwork

Picking the right materials for your duct system is a bigger deal than most homeowners realize. It's one of the most critical decisions in the entire installation of ductwork process. Think of it like the circulatory system of your home—the material you choose determines how efficiently air moves, how long everything lasts, and even your home's air quality.

Each material—sheet metal, flexible ducting, and duct board—has its own job. A seasoned pro knows that the best systems don't just use one type. They create a hybrid system, strategically combining materials to maximize airflow and work around your home's unique layout.

Rigid Sheet Metal Ducts

When you picture ductwork, you're probably thinking of rigid sheet metal. It’s typically made from galvanized steel or aluminum and is the undisputed champion for trunk lines—the main highways of your HVAC system. Its slick, smooth interior surface offers the path of least resistance, letting air flow effortlessly from your furnace or AC.

That smoothness is its secret weapon. Imagine trying to blow air through a smooth pipe versus a corrugated, bumpy one. You’d get a lot more airflow from the smooth one with the same amount of effort. That's how rigid ductwork operates, allowing your HVAC equipment to work smarter, not harder.

Thanks to its tough build, sheet metal is also incredibly durable. It stands up to accidental bumps or punctures, both during installation and for years after. This makes it a fantastic long-term investment for the core parts of your system that carry the most air.

Flexible Ducts

You’ll often hear these called “flex ducts.” They’re essentially a wire coil wrapped in durable plastic and insulation. Their biggest advantage? You can put them almost anywhere. Technicians rely on flex ducts to navigate tricky spots where rigid ductwork just won’t fit.

Think of those tight joist bays in the attic, cramped crawl spaces, or making that final S-turn to connect a main duct to a ceiling vent. That's where flex ducts come in, bridging the gap between the rigid system and the registers in your rooms.

But that flexibility has a downside. The ribbed interior creates more friction than smooth metal, which can slow down airflow if it’s not installed just right.

A professional installation is non-negotiable for flex ducts. They need to be pulled taut and supported properly. Any sags or sharp kinks will choke off airflow and starve a room of conditioned air.

Fibreglass Duct Board

Fibreglass duct board, or "ductboard," is a different beast altogether. It arrives as flat, compressed fibreglass sheets with a foil backing. Technicians cut and assemble these boards on-site to create custom-sized rectangular ducts.

Its main selling point is that the insulation is built right in. This makes it a go-to choice for runs in unconditioned areas like attics and garages, where it stops heat from escaping in the winter or creeping in during the summer.

As a bonus, the fibreglass material is a natural sound absorber, helping to quiet down the noise from your furnace fan and the rush of air. The key, however, is getting a perfect seal. Every seam and joint must be meticulously sealed with specialized tapes and mastics to prevent leaks. You can dive deeper into this topic in our guide on using mastic sealant for ductwork to achieve an airtight system.

To help you see the differences at a glance, here’s a quick comparison of the materials a professional might use in your home.

Comparison of Common Ductwork Materials

| Material Type | Best For | Pros | Cons |

|---|---|---|---|

| Rigid Sheet Metal | Main trunk lines and primary supply/return runs. | – Highest airflow efficiency – Extremely durable and long-lasting – Resistant to mould growth | – Higher material and labour cost – Requires insulation in unconditioned spaces – Difficult to install in tight spaces |

| Flexible Ducts | Connecting main ducts to room registers, navigating tight or awkward spaces. | – Very flexible and versatile – Lower installation cost – Good for oddly shaped areas | – Less efficient airflow due to ridges – Prone to kinks and sags if installed poorly – Less durable than sheet metal |

| Fibreglass Duct Board | Systems in unconditioned spaces where insulation and sound dampening are key. | – Excellent thermal insulation – Natural sound-dampening qualities – Lighter weight than sheet metal | – Fibreglass fibres can enter airstream if damaged – Susceptible to moisture and mould if not sealed – Requires careful sealing at all joints |

In the end, a high-performance system isn’t about choosing just one material—it’s about using the right material in the right place. By playing to each type’s strengths, a well-designed duct system will deliver quiet, efficient comfort throughout your home for decades.

The Professional Ductwork Installation Process

A professional ductwork installation is so much more than just connecting a few tubes together. It’s a carefully planned process where science and skilled hands come together to build the circulatory system for your home’s comfort. The whole thing starts long before the first piece of metal is cut—it begins with a deep dive into your home’s unique needs.

The very first step, and arguably the most critical, is the initial home assessment and load calculation. A true pro doesn’t just show up with a measuring tape. They’ll look at everything: window efficiency, insulation levels, even which way your house faces the sun. All this data gets plugged into a special formula (called a Manual J calculation) to figure out the exact heating and cooling "load" for your home as a whole and for every single room.

Think of it like getting a prescription from a doctor. A one-size-fits-all approach just doesn’t work. If the system is too small, it will run nonstop, struggling to keep you comfortable and sending your energy bills through the roof. Too big, and it’ll turn on and off so quickly that it can't properly remove humidity, leaving you with clammy air and annoying temperature swings. The load calculation makes sure the prescription is just right for your home.

From Blueprint to Reality: The Layout and Fabrication Stage

Once the numbers are crunched, the technicians get to work designing the system's layout. This is basically the roadmap for your home’s airflow, plotting the most direct and efficient path for air to get from your furnace or AC to every vent. The aim is to create a path of least resistance—the fewer sharp turns and long, winding runs, the better the airflow.

With the design locked in, it’s time for fabrication. This is where technicians start cutting and shaping the sheet metal, ductboard, or flex duct to the exact specs from the blueprint. This custom-fit approach is key because it leads to tight connections and way fewer leaks, which are a huge source of wasted energy in many homes.

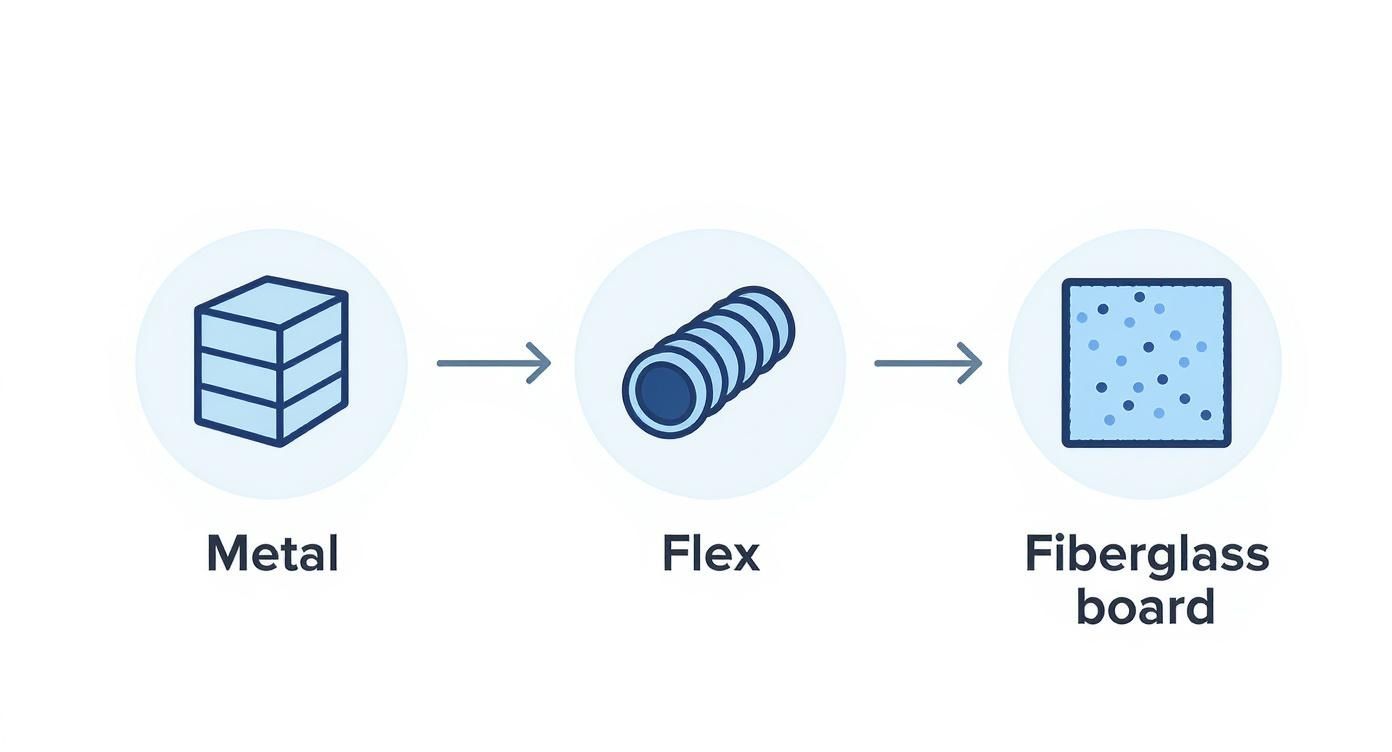

The infographic below shows how different materials are often used together in a modern hybrid system.

As you can see, sturdy metal usually forms the core of the system, while flexible and fibreglass ducts are used in specific spots where they make the most sense.

Assembling the System: Trunk Lines and Branches

The actual hands-on installation begins with the main arteries: the trunk lines. These are the big ducts that carry the main volume of conditioned air straight from your HVAC unit. Technicians carefully hang and secure these lines, making sure they’re supported properly so they don't sag over time, which can create bottlenecks and choke off airflow.

From these main trunks, smaller branch lines peel off to feed individual rooms, ending at the supply vents you see on your floors, walls, or ceilings. Every single connection point is a potential air leak, so this is where precision really matters.

A pro’s motto is "seal it right, seal it tight." Just shoving two ducts together and slapping some duct tape on it is a recipe for disaster. Real professionals mechanically fasten every joint with screws and then paint on a thick layer of mastic sealant. This creates a permanent, airtight bond that tape just can’t match.

This meticulous sealing is what makes the difference between a high-performance system and a leaky, inefficient one that costs you money every month.

Insulation, Sealing, and Final Checks

With the whole network built and sealed, it's time for the finishing touches. Any ductwork that runs through unconditioned spaces—think attics, crawl spaces, or garages—absolutely must be insulated. This step prevents thermal energy loss, which is just a fancy way of saying it keeps your warm air warm and your cool air cool on its journey to your living spaces. If you skip insulation, you’re basically paying to heat and cool your attic.

Throughout the installation, safety is always top of mind. For a look at general job site safety, you can review these Heavy Equipment Installation Safety Tips.

Finally, once everything is installed and wrapped, the technicians will run a series of tests to make sure the system is working as designed. This usually includes a final airflow balancing test to confirm each room is getting the right amount of air. To keep your new system working like new, it’s a good idea to keep it clean. You can check out our professional air duct cleaning services to maintain peak performance and great air quality for years.

Understanding Permits, Codes, and Installation Costs

Let's talk about the part of an installation of ductwork that can feel more intimidating than the actual work: the paperwork and the price tag. Getting your head around building permits, local codes, and the final invoice is key to making sure your project is legal, safe, and fairly priced.

First things first, this isn't a weekend DIY project. Professional ductwork installation is considered a major construction task. That means most municipalities across the Greater Toronto Area will require a building permit, especially if you're doing a full system replacement or adding ductwork for a new extension.

Getting a permit isn't just about red tape. It’s a safety net. It guarantees that a city inspector will sign off on the work, confirming it meets the Ontario Building Code. This is huge for your peace of mind, your home insurance, and your property's future value. Any reputable contractor will handle this entire process for you—it should be part of their service.

Navigating Local Building Codes

Building codes are the rulebook for your installation. They cover everything from the types of materials your contractor can use to how they must seal joints and support the ducts. For instance, codes will specify the minimum insulation R-value for ductwork running through unconditioned spaces like your attic, which is crucial for preventing heat loss. They also include strict fire safety rules, like requiring special fire-stopping materials where ducts pass through walls.

Adhering to building codes isn't optional—it's the law. A non-compliant installation is a recipe for disaster, potentially leading to failed inspections, expensive do-overs, and serious safety risks. This is exactly why you hire a licensed, experienced contractor who knows the code inside and out.

Breaking Down Ductwork Installation Costs

So, what should you expect to pay? The total cost of a ductwork project hinges on a few key factors. Knowing what they are will help you make sense of quotes and set a realistic budget.

- Home Size and Layout: It's simple—a bigger home needs more ductwork, which means more material and labour costs. Tricky layouts, like homes with multiple storeys or hard-to-access crawl spaces, also push the price up because they take more time and effort.

- System Complexity: Replacing an existing, straightforward system is always cheaper than installing a brand-new one in a home that's never had ductwork. If you need a custom design or have to integrate with specialized high-efficiency equipment, that will add to the cost as well.

- Material Choice: As we covered earlier, rigid sheet metal costs more upfront than flexible ducts or fibreglass duct board. The labour to install it is also more intensive, which is reflected in the final bill.

- Labour Rates: You'll see different labour rates across the GTA. Highly experienced, licensed technicians charge more, but their expertise is often worth it. They get the job done right the first time, saving you money and headaches down the road.

For a typical single-family home in the Toronto area, a complete ductwork replacement can run anywhere from $3,000 to $8,000 or more, depending on these variables. If you're just adding ducts for a basement reno, you might be looking at something in the $1,500 to $3,000 range.

Often, this work is part of a larger HVAC upgrade. If a new furnace is on your radar, you can get a better sense of the big picture by reading our guide on furnace with installation costs. The best advice? Always get a few itemized quotes to compare apples to apples.

How Professionals Ensure Peak Performance After Installation

When the installer tightens that last joint, the job isn’t truly finished. Seasoned technicians know the real magic happens during system commissioning—a hands-on, methodical check that turns raw ducts into a finely tuned airflow network.

Skipping this step is like buying a high-performance car and never taking it in for a tune-up. You need commissioning to verify every component works together, so your investment delivers the comfort and efficiency you expect.

The Science Of Airflow Balancing

Imagine dividing water from a single hose into buckets of different sizes. You wouldn’t flood the small pail or trickle into the big one. Airflow balancing does the same for your home’s supply vents.

Technicians measure the cubic feet per minute (CFM) at each outlet using an anemometer. Then, they adjust the dampers nestled inside the duct runs until the flow matches the blueprint.

- Measure CFM at each supply vent

- Compare readings to design specifications

- Fine-tune dampers to correct discrepancies

- Re-verify until every room hits its target airflow

Without this process, some rooms will bake while others shiver—an all-too-common sign of an unbalanced system.

Checking The System’s Vital Signs With Static Pressure Testing

If airflow is volume, static pressure is the push. Think of it as your HVAC’s blood pressure. A manometer reveals how hard the furnace or AC fan works to force air through the network.

- High Static Pressure: Signals a restriction—maybe a blocked filter or cramped duct run—forcing the fan to overexert itself.

- Low Static Pressure: Often points to big leaks or ducts that are too large, meaning conditioned air simply escapes into the structure.

Keeping static pressure within the manufacturer’s recommended range ensures your system “breathes” easily. At this stage, it’s wise to familiarise yourself with the essential duct cleaning equipment professionals use to maintain peak performance over time.

The Critical Role Of Sealing And Insulation

Even the most meticulous balancing and pressure checks can’t overcome leaky ducts. Every seam and joint needs an airtight seal with mastic or HVAC-rated foil tape.

A leaky duct system is like trying to fill a bucket with holes in it. You’re constantly losing what you’ve paid for before it can do its job.

Research shows that some homes lose 29% to 78% of conditioned air through unsealed ductwork. You can read more about these findings on the U.S. Department of Energy website.

Finally, any duct runs through attics or crawl spaces must be hand-wrapped in insulation. This thermal barrier stops your winter warmth or summer cool from vanishing into unconditioned areas, locking in comfort and efficiency.

Common Questions About Ductwork Installation

Home projects of this scale naturally raise questions. It’s one thing to read about ductwork, but quite another to live through an installation. Whether you’re worried about disruptions, costs, or the right contractor, these answers will put you at ease.

Our goal is to demystify the process and prepare you for a hassle-free upgrade. Once you know what’s coming, you’ll feel confident about improving your home’s comfort and efficiency for years to follow.

How Long Does a Typical Ductwork Installation Take?

When should you clear your calendar? Timelines vary by project type:

- New Build: Installing ducts in a home under construction usually wraps up in 3 to 5 days, thanks to open walls and ceilings.

- Full Replacement: Swapping out an existing system takes 2 to 7 days, depending on your home’s size, age and layout.

- Additions & Renovations: Running a single new duct—say, for a basement makeover— often lands in 1 to 2 days.

Every contractor should provide a detailed schedule before breaking ground.

Can I Install My Own Ductwork to Save Money?

It might be tempting to grab a roll of flexible duct and go for it, but DIY ductwork often costs more in the long run. Proper sizing and layout rely on methods like Manual J and Manual D calculations to balance airflow and protect your HVAC unit.

Incorrect ducts don’t just underperform—they can overload your furnace or air conditioner, shorten equipment life and send your energy bills skyrocketing.

A licensed professional ensures safety, code compliance and long-term efficiency.

What Are the Signs My Existing Ductwork Needs Replacement?

Ducts can hide problems until they become costly headaches. Watch for:

- Rising Energy Bills that don’t match your usage

- Temperature Swings—rooms that never feel quite right

- Unusual Noises, such as rattles or whistles from your vents

- Excess Dust settling on surfaces, hinting at leaks

- Visible Damage on ducts older than 20 years, including tears or rust

Spotting these issues early lets a pro recommend repairs or a full replacement before comfort and efficiency suffer.

How Do I Choose the Right HVAC Contractor?

Your ductwork’s performance depends on the installer. Follow these steps:

- Verify they’re licensed and insured in Ontario

- Seek specialists with ductwork design and installation expertise

- Read online reviews and ask for local references

- Require an in-person assessment—no phone estimates

- Get a detailed, itemized quote covering materials, labour and permits

- Confirm warranties on workmanship and parts

This approach helps you select a team that stands behind their work.

A well-installed duct system lays the groundwork for a comfortable, energy-efficient home. At Can Do Duct Cleaning, our certified technicians design and install ductwork tailored to your space. Ready for an assessment or have more questions? Visit us online to see how we can enhance your indoor air quality and comfort.