A proper air duct installation is about so much more than just connecting a few tubes. Think of it as building the circulatory system for your home’s air. A well-designed, tightly sealed ductwork system is what gets heated or cooled air where it needs to go, and getting it right affects everything from your family's comfort to your monthly energy bills.

Honestly, this initial planning is the most critical part of the whole job.

Laying the Groundwork for Your Ductwork Project

Before you even touch a pair of snips, it’s worth taking a step back to understand the basics of how your HVAC system breathes. This knowledge alone can help you sidestep common DIY blunders that lead to lousy performance, sky-high energy costs, and even a strained HVAC unit. It all begins with picking the right materials and respecting the physics of airflow.

A good system is a delicate dance. You need to move enough air to keep a room comfortable, but you need to do it quietly and without wasting energy. This is all about balancing airflow and static pressure. I like to think of static pressure as the "blood pressure" of an HVAC system—if it’s too high, the whole system is working overtime. Too low, and that warm air will never quite make it to the chilly back bedroom.

Choosing the Right Duct Material

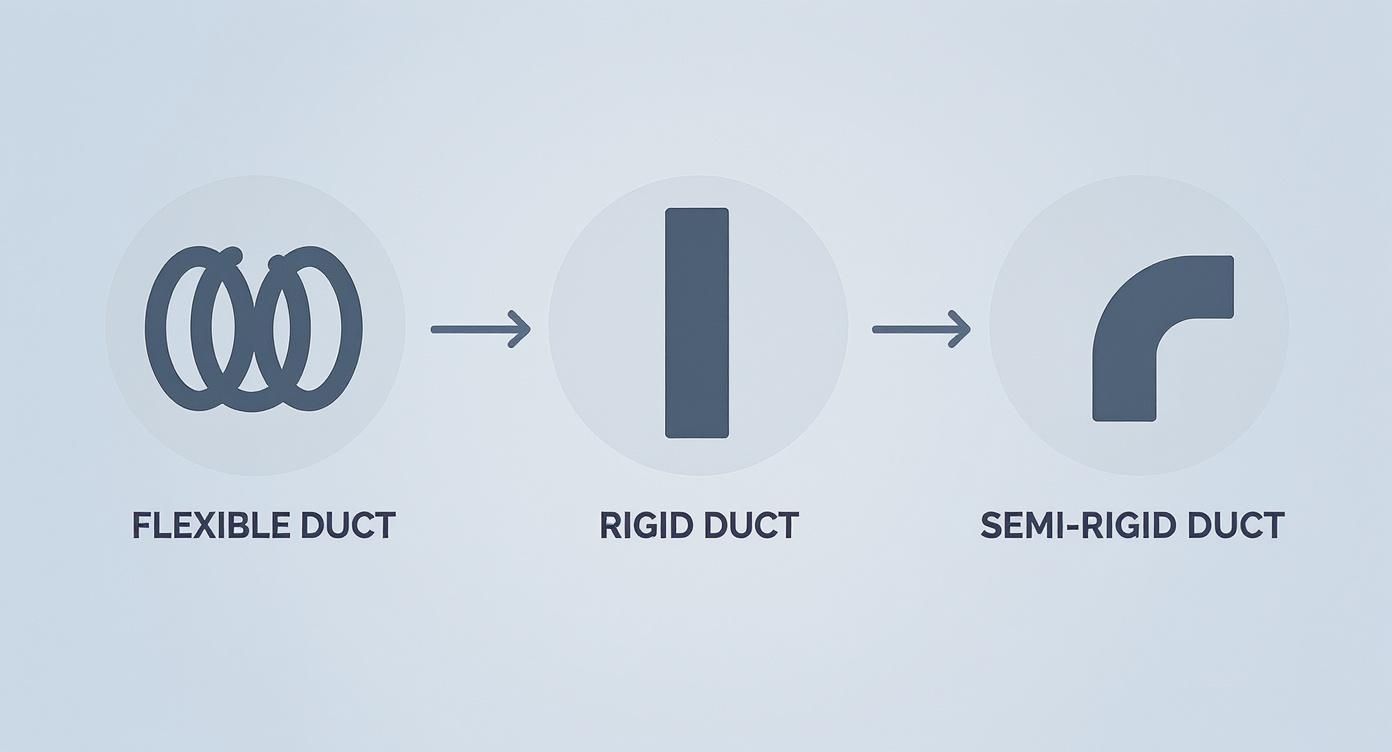

The ducting you choose will really depend on your home's unique layout, your budget, and how much space you have to work in. Each material has its place, and knowing where to use what is key.

- Rigid Ducts: Made from galvanized steel or aluminum, these are the undisputed champions for durability and airflow. Their smooth interior means less resistance, letting air travel freely. I always recommend these for the main "trunk" lines of your system.

- Flexible Ducts: You’ve probably seen these accordion-style insulated tubes. They’re a lifesaver for installing in tricky spots, like weaving around joists in an attic. The catch? They create more friction. To avoid choking off airflow, you have to install them properly—pulled taut with as few bends as possible.

- Semi-Rigid Ducts: Think of these as a nice middle ground. They’re often used for specific jobs like dryer vents. They offer more strength than flex ducts but still give you some maneuverability.

A classic hybrid approach I see all the time is using rigid ductwork for the main supply and return trunks in an accessible basement. Then, you can transition to short, straight runs of flex duct to connect to the vents in each room. It gives you the best of both worlds: the efficiency of rigid ducts paired with the convenience of flex where you need it most.

A leaky duct system can lose 20% to 30% of the conditioned air passing through it. That’s a staggering amount of waste. Choosing the right materials and sealing every joint meticulously is your best defence.

The Legal and Quality Assurance Side

Getting the physical parts right is one thing, but you also have to consider local rules and the overall health of your home. Before you start, look into your local construction permit requirements. A major HVAC project like a full duct installation often requires a permit to ensure everything is done safely and to code.

Beyond that, think about the air that's going to be flowing through these shiny new ducts. A new system is great, but it will still circulate dust, allergens, and whatever else is floating around if your home's air quality is poor to begin with. It’s a smart move to get a baseline with professional indoor air quality testing. This step ensures your new ductwork is delivering genuinely clean, fresh air from the moment you turn it on.

Designing an Efficient Ductwork Layout for Your Home

The blueprint you draw up is without a doubt the most important part of a successful air duct installation. A solid, well-considered plan is what guarantees every room gets the right amount of conditioned air, finally getting rid of those annoying hot and cold spots. This is the moment you go from just having a pile of parts to engineering a system that actually performs.

Your real goal here is to create a balanced network. I always tell homeowners to think of it like a city's water supply—you have big main lines (the trunks) carrying huge volumes, and smaller pipes (the branches) to get it to each house without losing pressure. Your ductwork runs on the exact same principle, using static pressure to push air where you need it to go.

Starting with a Room-by-Room Assessment

Before you even think about sketching a layout, you need to get a feel for what each room actually needs. A big living room with a wall of sun-facing windows has totally different cooling demands than a small, shaded powder room. This is where a simplified load calculation becomes your best friend.

You don't need fancy software for a decent DIY estimate. Just start by measuring the square footage of each room and making notes on anything that affects the temperature.

- Window Exposure: Which way do the windows face? South-facing windows bring in a ton of heat.

- Occupancy: How many people are usually in the room? A busy family room needs more airflow than a spare bedroom.

- Insulation Levels: Is the room sitting over a cold garage or right under a hot, uninsulated attic?

- Electronics: Is this the media room with a big TV, gaming console, and computer setup all generating heat?

This quick room-by-room analysis helps you ballpark the required CFM (cubic feet per minute) for each space. That number tells you what size duct and register you'll need to serve it properly. A common rule of thumb is roughly 1 CFM per square foot, but you'll need to adjust that up or down based on the factors you just noted.

Mapping Your Ductwork Pathways

Once you have your room needs figured out, grab a pencil and some graph paper (or fire up some simple design software) and sketch your home’s floor plan. Now the fun begins—mapping out the most efficient routes for your supply and return duct lines. The golden rule here is simple: keep your runs as short, straight, and direct as you possibly can.

Every single bend, turn, and long, meandering stretch adds resistance, making your HVAC unit work harder and costing you money. For a typical single-story home, running the main trunks down a central hallway in the attic or crawlspace is often the best bet. If you're in a two-story house, you might run a main trunk in the basement for the first floor and a second one in the attic for the upstairs, using chases hidden in closets to connect everything vertically.

An efficient layout is the absolute foundation of a high-performing HVAC system. Your design must prioritize minimizing static pressure by using the straightest, most direct paths for airflow. This one principle will have the biggest impact on both your family's comfort and your long-term energy bills.

A well-designed ductwork system is a critical part of making your HVAC system energy efficient, directly contributing to lower energy consumption and better performance.

Considering Duct Types in Your Design

The layout you create will also help you decide which duct material is the right choice for each section. This infographic gives a great overview of the common options and where they're typically used.

As you can see, rigid metal ducts are perfect for the main trunk lines because their smooth interior surface creates very little friction. On the other hand, flexible ducts are a lifesaver for connecting those trunks to individual room registers, especially when you have to navigate tight corners and awkward spaces.

Finally, one of the biggest oversights I see in DIY designs is forgetting the return air system. It’s just as important as the supply side. You can learn more in our guide on the air ducts system you shouldn't be ignore. Putting in the effort to plan properly at this stage is what sets you up for a smooth installation and years of reliable comfort.

Assembling the Right Tools and Materials

There’s nothing worse than getting halfway through an air duct installation only to realise you’re missing a critical tool or fitting. It kills your momentum and turns a productive day into a frustrating trip back to the hardware store.

Before you make a single cut, take the time to gather everything you need. Think of it like a chef preparing their ingredients—having everything laid out and ready makes the entire process smoother, safer, and far more professional. Investing in quality essentials pays off with cleaner cuts, tighter seals, and ductwork that’s built to last.

Let's walk through the exact tools and materials you'll want on hand.

Getting your tools and materials in order is the first real step toward a successful installation. The following table breaks down what you'll need, what it does, and what to look for when you're buying.

Essential Tools and Materials for Air Duct Installation

| Item | Primary Function | Selection Tip |

|---|---|---|

| Tin Snips (Aviation Snips) | Cutting sheet metal | Get a set of three: left-cut (red), right-cut (green), and straight-cut (yellow) for maximum control and clean cuts. |

| Duct Crimper | Shrinking the end of a round duct | This is non-negotiable for fitting one piece of round duct into another. Look for a sturdy tool with comfortable grips. |

| Hand Seamer | Bending and folding sheet metal | Indispensable for creating custom connections and finishing edges. A 3-inch model is a great all-rounder. |

| Mastic Sealant | Creating airtight seals on all joints | This is far superior to tape. Choose a water-based duct sealant that’s easy to apply and clean up. |

| Caulking Gun | Applying mastic sealant | Don't skimp here. A high-quality, high-thrust caulking gun will save your hands when applying thick mastic. |

| Ductwork (Rigid & Flexible) | Carrying air through the system | Use rigid metal for the main trunk lines and insulated flex duct for final runs to individual rooms. |

| Takeoffs & Fittings | Connecting duct runs to the plenum | Ensure you have the correct size and shape (round, square) for your specific design plan. |

| Register Boots & Grilles | Terminating duct runs at the vent opening | Match the boot to your duct size and the grille style to your home’s decor. |

| Dampers | Regulating airflow | Install these in branch lines to balance the system and ensure even heating and cooling throughout the house. |

| Hangers & Straps | Supporting the ductwork | Use metal straps to prevent sagging, which can lead to poor airflow and moisture problems. |

| Safety Gear | Protecting yourself | Always use heavy-duty gloves to protect from sharp metal edges and safety glasses to shield your eyes. |

With this checklist, you can be confident you have everything required to tackle the job from start to finish without any last-minute surprises.

Choosing the right sealant is one of the most critical decisions in your project. While foil tape has its uses, mastic sealant is the professional's choice for creating a permanent, flexible, and truly airtight seal that won't degrade over time like tape adhesives can.

Finally, don’t overlook the smaller details that make a huge difference. You'll need insulation with the proper R-value for your climate, especially for any ducts running through unconditioned spaces like attics or crawlspaces. This is key to preventing energy loss.

This level of preparation ensures your new system runs at peak efficiency from day one. And remember, good system maintenance, like keeping an eye on your furnace filter, is just as important. For more on that, check out our guide on when to replace your furnace air filter.

A Practical Guide to Installing and Sealing Your Ductwork

With your design locked in and materials at the ready, it's time to roll up your sleeves and bring your air duct installation plan to life. This is where meticulous work really shines, turning a pile of metal and tubing into a high-performance system that keeps your home comfortable.

Think of yourself as an air traffic controller. Your job is to create smooth, clear pathways for heated or cooled air to travel from your furnace or AC to every single room. A crushed flex duct here or a sagging trunk line there can create turbulence, tank your efficiency, and undo all the hard work you've put in so far.

Cutting and Connecting Your Ductwork

First up is cutting your rigid ductwork to the lengths you mapped out in your design. Use your aviation snips for clean, straight cuts, and please—wear heavy-duty gloves. Freshly cut sheet metal is sharper than you think.

Once a piece is cut, it needs to connect to the next section or fitting. This is where a duct crimper becomes your best friend. By crimping one edge, you shrink its diameter just enough for it to slide snugly into the next piece. Secure that connection with at least three evenly spaced sheet metal screws for a solid mechanical bond.

You'll repeat this process for all your main connections:

- Plenum Takeoffs: These are the starting blocks, attaching directly to the main plenum on your furnace or air handler.

- Trunk Line Sections: This is how you'll connect the long, straight runs of your main supply and return lines.

- Branch Duct Taps: These fittings are where smaller branch ducts peel off from the main trunk line to feed individual rooms.

Working with flexible ducts is a bit different but just as crucial. After cutting a section to length with a utility knife, peel back the outer insulation to expose the inner liner. Slide that liner over the collar of the register boot or takeoff, then pull it tight with a zip tie. Finish by pulling the insulation and vapour barrier back over the joint and securing it all with another zip tie.

The Critical Art of Sealing Every Seam

This next step is the single most important thing you can do for energy efficiency: sealing every connection. A leaky, unsealed duct system can lose 20% to 30% of the conditioned air moving through it. That’s a massive waste.

This is exactly why you bought that bucket of mastic sealant. Mastic is a thick, gooey paste that dries into a tough, rubbery seal that, unlike tape, won't degrade or peel away with temperature swings. Using a caulking gun or a cheap paintbrush you don't mind throwing away, slather a thick layer over every single joint, seam, and screw head on your rigid ducts.

Don't be shy with the sealant. The goal is to create a completely airtight system. Every connection, no matter how small, is a potential leak if not sealed correctly. A truly professional air duct installation is defined by its meticulous sealing.

Pay extra attention to notorious leaky spots, like where a takeoff meets the plenum or where a register boot pushes through the drywall. For a deeper dive into why this stuff is so effective, our guide explains the benefits of using mastic sealant for your ductwork.

Supporting Your Ductwork for Longevity

Ducts can't just hang in space—they need proper support to maintain airflow and prevent damage. Heavy metal ducts will sag over time if they aren't hung correctly, creating low spots where moisture can pool or airflow gets restricted. Use metal hanging straps every 8 to 10 feet for rigid ducts, making sure there's no sag between supports.

Flexible ducts are even more finicky. You need to support them every 4 to 5 feet to stop them from kinking or sagging, which will choke off airflow almost instantly. Use straps to create a gentle "saddle" for the duct to rest in; never pinch or crush it. And remember, keep your flex duct runs as short and straight as you possibly can.

This meticulous approach isn’t just about doing a good job; it’s often the law. As provinces push for more energy-efficient homes, building codes are getting stricter about ductwork performance. In places like Ontario and BC, new building codes mandate specific sealing and insulation standards to ensure systems are optimized from day one.

How to Test Your System and Avoid Common Pitfalls

An air duct installation isn't over just because the last screw is in place. The real finish line is confirming everything works exactly as it should. This is where you put your work to the test and make sure you haven't stumbled into any common DIY traps.

Think of this as your own quality control check. It's how you spot the little things before they snowball into big problems, ensuring your new system gives you balanced airflow, top-notch efficiency, and comfortable rooms for years to come. A few checks now will save you a world of frustration and high energy bills down the road.

Performing Initial System Checks

Before you pack up your tools, run through a few simple tests to get a gut feeling for how the system is performing. You don't need any high-tech gear for this—your own eyes and hands are surprisingly effective.

First, do one last visual sweep. Trace the path of your ductwork from start to finish, eyeing every connection, support strap, and sealed joint. Are there any saggy spots, kinks in the flex duct, or places where the mastic looks a little thin? It’s a thousand times easier to touch up a missed spot now than after the drywall is back up.

Next up is the "hand test." Flip your HVAC system’s fan on and walk to every single supply register in your house. Hold your hand over each one and pay attention.

- Feel the Flow: Is the air coming out with some force? If it’s weak or you can barely feel it, you might have a blockage, a crushed duct, or a major leak nearby.

- Compare Rooms: How does the airflow in the bedroom at the far end of the house compare to the living room right beside the furnace? Big differences suggest your system isn't balanced properly.

This simple, hands-on check gives you a real-world idea of whether your layout is actually getting air where it’s needed.

Understanding Professional Duct Leakage Testing

If you want the ultimate proof of a job well done, a professional duct leakage test is the way to go. A certified technician uses a special machine—often called a duct blaster—to pressurize the entire system.

This tool measures the exact amount of air escaping from unsealed joints, tiny cracks, or gaps. The readout gives you a clear, data-backed score on your system's efficiency. While it’s not something most DIYers do, knowing how it works really drives home just how critical every single seal is for performance.

A leaky duct system can be a massive energy hog, responsible for up to 30% of a home's heating and cooling costs. That makes meticulous sealing one of the most important parts of any duct installation project.

Sidestepping Common Installation Mistakes

I've seen a few common, and totally avoidable, mistakes trip up countless DIY projects over the years. Keep these in mind from the start, and you’ll be on your way to a pro-level result.

- Using Sharp 90-Degree Bends: Air hates making sharp turns. Every hard 90-degree angle creates a bottleneck, restricting flow and making your furnace or AC work much harder than it needs to. Always opt for gentle, sweeping curves or a pair of 45-degree elbows to keep the air moving smoothly.

- Undersizing Return Air Ducts: The return ducts are just as vital as the supply ducts. If they’re too small, they can literally starve your HVAC unit for air. This puts a huge strain on the fan motor and kills your efficiency. A good rule of thumb is to make sure your return capacity is at least equal to your supply capacity.

- Relying Only on Foil Tape: Foil tape has its place, but it's not a permanent seal. The adhesive gets brittle and fails over time as it goes through hot and cold cycles. For a durable, flexible, and truly airtight seal on every connection, mastic sealant is the only way to go.

By running these final checks and steering clear of these common errors, you're setting your home up for years of efficient comfort. A well-installed system is also a cornerstone of a healthy home. To see how it all connects, take a look at our guide on how to check the air quality in your home—your new ductwork plays a huge role.

Got Questions? Let's Talk Air Duct Installation

Even after mapping out the whole project, it's totally normal to have a few questions buzzing around. Installing a new air duct system is a massive job, and you want to be sure about everything from the cost to the timeline before you even think about cutting into drywall.

Let’s clear up some of the most common things homeowners ask when they're getting ready to dive in.

Cost is always top of the list. While you’re saving a bundle on labour by doing it yourself, the materials can still make a dent in your wallet. Lately, total costs for an air duct installation in California have climbed, with most homeowners spending somewhere between $2,000 to $7,500. For a typical 1,500 to 2,500 square-foot house, you're probably looking at the $3,000 to $5,000 range. For a deeper dive into pricing, check out this guide on ductwork installation costs from Angi.com.

Of course, these numbers swing wildly depending on how complex your home’s layout is and the type of ducting you pick. This is exactly why a detailed plan and a shopping list are your best friends for keeping that budget under control.

How Long Will This Actually Take Me?

Honestly, this depends entirely on your skill level, the size of your home, and how easy it is to get around in your attic or crawlspace.

- For a small, single-storey home (under 1,500 sq. ft.): If you've got a straightforward layout and you're working in an open basement, a handy person could probably knock this out over a long weekend.

- For a larger or multi-storey home: Be realistic and block off at least 4-7 full days. Working around multiple floors, squeezing into tight attics, and navigating tricky joist systems eats up a lot of time.

Don't forget to build in extra hours for planning, trips to the hardware store, and a proper cleanup. Rushing is the fastest way to make mistakes, especially when you get to the sealing stage—which is the most important part.

Can I Just Reuse Some of My Old Ductwork?

It’s tempting, I get it. You see a straight run of old duct and think, "Why not?" But it's almost always a bad move.

Old ductwork is a triple threat: it's likely inefficient, leaky, and filled with decades of dust, dander, and who knows what else. On top of that, older ducts were often built for less powerful HVAC systems. Hooking them up to a modern, high-efficiency unit is like trying to breathe through a coffee stirrer—it just suffocates your new system's performance right from the start.

Starting fresh with all-new, properly sized, and meticulously sealed ductwork is one of the best investments you can make in your HVAC system's longevity and efficiency. It ensures you get the full performance you're paying for from your furnace and air conditioner.

Do I Really Need a Permit for This?

In most places, including across the Greater Toronto Area, ripping out and installing a new duct system isn't just a weekend project—it's a major mechanical job that requires a building permit. This isn't just red tape; it's about safety.

A permit triggers an inspection to make sure your work is up to local building codes for things like fire safety, proper airflow, and energy efficiency.

Before you buy a single tool, call your local municipal building department. Skipping this step can lead to hefty fines and create major headaches when you eventually sell your home.

A DIY duct installation can be an incredibly satisfying project, but it demands a lot of time, patience, and know-how.

If you want the peace of mind that comes with a professional, code-compliant installation that guarantees your system runs at peak performance, trust the experts at Can Do Duct Cleaning. Our experienced technicians make sure every joint is sealed and every run is perfect.