A proper dryer vent installation is about so much more than just connecting a hose. It’s a critical project that protects your home and keeps your dryer running efficiently. This means creating a dedicated, clear path for hot air, moisture, and flammable lint to get from your dryer safely outside.

Why Your Dryer Vent Installation Matters

It’s easy to overlook your dryer vent. Most people see it as a simple hookup, but the truth is, a poorly installed vent can create serious risks for your home and family. Getting it right isn’t just a chore; it’s a non-negotiable safety measure.

The Overlooked Fire Hazard

The biggest danger of a bad dryer vent setup is, without a doubt, fire. Your dryer produces a ton of lint with every load—and that stuff is incredibly flammable. When a vent is too long, has a bunch of sharp bends, or uses flimsy vinyl or foil accordion hoses, lint gets trapped.

This buildup chokes off the airflow, which causes the dryer to overheat. You end up with intense heat right next to a pile of tinder-dry fuel. It’s a recipe for disaster. Research from the U.S. Fire Administration shows that thousands of house fires every year are caused by clothes dryers, with "failure to clean" being a top contributor.

A clean, properly installed vent is your number one defence against a dryer-related house fire. The goal is to give lint no place to hide and heat no reason to build up.

Carbon Monoxide and Moisture Risks

If you have a gas dryer, the stakes are even higher. A blocked or improperly sealed vent can send deadly carbon monoxide (CO) flowing back into your home instead of outside. Since CO is odourless and colourless, you might not know there's a problem until it's too late.

Beyond that, every dryer load expels gallons of moisture. If that damp air gets trapped inside your walls or attic, you’re looking at a future of mould, mildew, and even structural rot. A solid vent installation is crucial for your home's overall health, especially in keeping moisture out of your attic. For more on this, check out these excellent attic and roof ventilation tips.

Efficiency and Appliance Longevity

A poorly routed vent hits your wallet, too. When airflow is restricted, your dryer has to work way harder and run longer to get the job done. This leads to a few problems:

- Higher energy bills: Your dryer uses more electricity or gas just to keep up.

- Premature wear and tear: The constant strain on the heating element and motor can lead to expensive repairs and a much shorter lifespan for your appliance.

If you’ve noticed your clothes are still damp after a full cycle, that's one of the classic warning signs of a clogged or inefficient vent that needs your attention right away. Simply put, investing in a proper installation pays for itself in safety, lower utility bills, and a dryer that lasts.

Planning Your Route and Gathering Your Tools

Any pro will tell you that a top-notch dryer vent installation is 90% planning. Before you even touch a drill, mapping the vent's path from the back of your dryer to the outside is the single most critical step. Getting this right from the start saves a ton of headaches and ensures your system runs safely and efficiently.

The golden rule here is simple: the shortest, straightest path is always the best path. Think of it like a waterslide—the fewer twists and turns, the faster everything flows. Every bend and extra foot of ducting slows down airflow and gives flammable lint a place to build up.

Charting the Most Efficient Course

First things first, stand behind your dryer. Can you go straight through the nearest exterior wall? If so, you've hit the jackpot. This is the ideal setup, common in main-floor laundry rooms, as it uses the least material and gives you the best performance.

But what if a straight shot isn't an option? You might need to route the vent down through a crawlspace or up through the attic. Venting through the roof is a common solution, particularly in newer homes, but it comes with its own set of problems. Roof caps are notorious for clogging with lint and can be a real pain (and a safety risk) to clean.

My two cents: I always recommend terminating on a side wall if you can. Exiting through the rim joist is far easier to access for cleaning, less likely to cause leaks than cutting a hole in your roof, and almost always results in a shorter overall vent length.

Before you commit, it's time to play detective. Grab a stud finder and map out the framing in your target wall. You need to find a clear path between two studs. Just as important, you need to be aware of what you can't see—plumbing, electrical wires, and other HVAC runs are often hiding in walls. Slicing into one of those can turn a weekend DIY into a very expensive phone call to a contractor.

Getting Your Toolkit and Materials Ready

Showing up to the job with the right gear is non-negotiable. A safe and effective installation depends entirely on using the correct, code-compliant materials. Those flimsy, white vinyl or foil accordion-style hoses you see at the hardware store? They're a major fire hazard and are banned by most building codes for a reason.

Before you start, it’s best to have everything you need laid out and ready to go. Here’s a rundown of what a professional setup looks like.

Your Complete Dryer Vent Installation Toolkit

| Item Category | Specific Item | Purpose and Notes |

|---|---|---|

| Ducting | 4-inch Rigid Metal Duct | Smooth-walled aluminum or galvanized steel. The smooth interior is key to preventing lint buildup. |

| Fittings | Adjustable Metal Elbows | For navigating corners. Try to use no more than two 90-degree elbows in the entire run. |

| Termination | Exterior Vent Cap | Get a quality one with a pest guard and a damper to keep critters and cold air out. |

| Sealing | Aluminum Foil Tape | This is a must. Regular duct tape will dry out and fail. This tape is made for high heat. |

| Fasteners | Metal Worm-Gear Clamps | Used to secure the flexible transition hose to the dryer and the rigid ducting. |

| Tools | Drill & 4.25-inch Hole Saw | Creates the perfect-sized, clean opening through your wall and siding. |

| Tools | Stud Finder | Essential for locating a clear path through the wall and avoiding pipes or wiring. |

| Safety | Safety Glasses & Gloves | Protect your eyes from debris and your hands from sharp metal edges. |

Having all this on hand ensures you won't be tempted to cut corners with the wrong parts.

Once your new vent is installed, keeping it clean is the next crucial step for safety and efficiency. To understand what's involved, you can learn more about a professional dryer vent cleaning service and how it keeps your home safe.

Executing a Safe and Secure Installation

Alright, you’ve got your route planned and your gear is laid out. Now for the hands-on part of the dryer vent installation. This is where a bit of patience and precision really pays off, ensuring you end up with a system that's safe, efficient, and built to last.

We're aiming for clean cuts, solid connections, and a completely airtight seal from your laundry room to the outside world. Taking your time here is the key to preventing annoying air leaks, moisture issues, and dangerous lint buildup down the road. Let’s get to it.

Creating the Openings Inside and Out

The first real step is making the hole for the vent to pass through. This means cutting two perfectly aligned holes—one on the inside wall and one on the outside. The secret to getting this right is the pilot hole.

From inside your laundry room, take a long, thin drill bit and drill straight through the wall at the exact centre of your planned exit point. Push it all the way through to the outside. This little hole is your guide, guaranteeing your inside and outside cuts line up. Trust me, there's nothing more frustrating than cutting a big hole only to find it's in the wrong spot on the other side.

With the pilot hole in place, you can tackle each side.

- Interior Hole: Pop your 4.25-inch hole saw onto your drill. Using the pilot hole as your guide, cut right through the drywall. Keep it steady.

- Exterior Hole: Head outside and do the same thing. The material here will likely be tougher—think wood sheathing, vinyl, or even stucco—so let the saw do the work with firm, steady pressure.

Pro Tip: If you're drilling through vinyl siding, run your drill in reverse for a few seconds first. This scores the surface and prevents it from cracking. Once it's scored, switch to forward and complete the cut. It's a small trick that saves you from a big headache and ugly cosmetic damage.

Assembling and Securing the Ductwork

Now it's time to build the vent run itself. Start at the exterior by connecting the first piece of rigid duct to your vent cap. A worm-gear clamp will hold it temporarily. Slide the cap into place from the outside, making sure it sits flush against the siding and the damper flap can move without catching. Secure the cap with some good exterior-grade screws.

Working your way from the outside in, start fitting your rigid metal duct sections together. Each piece should slide neatly into the next. One crucial detail: the male (crimped) end of the duct must always point in the direction of the airflow—towards the outside. This little detail creates a smooth interior surface that stops lint from snagging on the seams.

At every single joint where two pieces of pipe or an elbow connect, you need to seal it with aluminum foil tape. This is absolutely non-negotiable. Regular duct tape will just dry out from the heat and fail, but this specialty tape creates a permanent, airtight seal. It stops hot, moist, lint-filled air from escaping into your walls or ceiling.

Supporting Long Runs and Preventing Sags

If your vent run is longer than a few feet, especially if it's running horizontally across a basement ceiling, it needs proper support. Without it, the duct will eventually sag under its own weight. Those sags become traps for lint and moisture, leading to a serious blockage.

To stop this from happening, use metal hanger straps every four to five feet to fasten the ductwork securely to joists or wall studs. You want to maintain a slight but consistent upward slope towards the outside exit—aim for about a quarter-inch of rise for every foot of run. This helps moisture drain out and makes it tougher for lint to settle.

Final Connections and Weatherproofing

The last piece of the puzzle is connecting the whole system to your dryer. This is usually done with a short, semi-rigid transition hose. Attach one end to the rigid duct coming through the wall and the other to the exhaust port on the back of your dryer.

Use worm-gear clamps to secure both ends. Whatever you do, don't use screws. The sharp points can poke into the duct and catch lint, which is the exact fire hazard you're trying to prevent. Carefully slide the dryer back, making sure you don't crush or kink the hose. A crushed hose is one of the most common reasons for poor airflow.

For the final touch, go back outside. Run a bead of exterior-grade, weatherproof silicone caulk around the entire edge of the vent cap where it meets the siding. This creates a lasting, waterproof seal that keeps rain, snow, and pests out of your wall. It's also a good idea to understand common dryer vent cleaning mistakes to avoid to keep your new system working perfectly.

Once everything is connected and sealed, run your dryer on an air-fluff cycle for a couple of minutes. Go outside and feel the air coming from the vent cap. You should feel a strong, steady airflow, and the damper should be wide open. That's your confirmation of a successful dryer vent installation.

Navigating Local Building Codes

Getting your dryer vent installation right isn't just about making it work—it's about making it safe and legal. Local building codes can feel like a lot of red tape, but they’re actually there to prevent fires and keep your home safe. Getting a handle on them now means you won’t have any nasty surprises during a future home inspection.

While the specific rules can differ slightly from one municipality to another across the Greater Toronto Area, the main goals are always the same: ensure great airflow and reduce fire risk. If you ignore these guidelines, you could be creating a serious hazard, no matter how good the installation looks on the surface.

To make sure your project is up to snuff, you'll need to know what your local area requires and understand what a building permit entails.

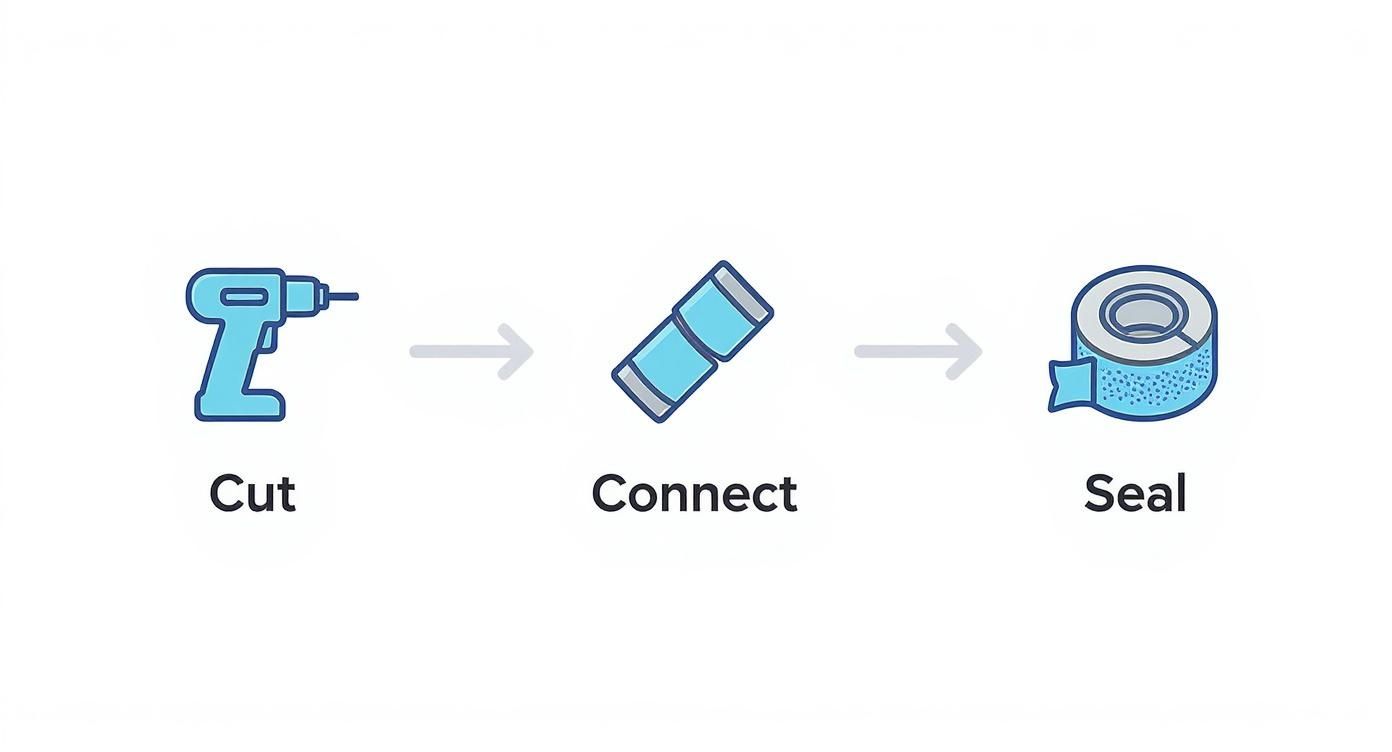

Every compliant installation follows the same basic, safety-first logic: you cut clean openings, connect the ductwork securely, and seal every single joint without compromise.

This simple breakdown shows how each step plays a crucial role in building a safe, efficient system that meets strict building standards.

Core Code Requirements You Cannot Ignore

Alright, let's get into the non-negotiables. First up: the material. The building code is crystal clear on this point. You absolutely must use smooth-walled rigid metal ducting that's at least four inches in diameter. Those cheap, flexible vinyl or foil ducts? They're completely banned for any installation that’s hidden in a wall or ceiling, and for good reason—their accordion-like design is a lint-trap waiting to happen.

Another huge one is how you fasten the sections together. You should never use screws. The points of the screws poke into the duct and act like little hooks, grabbing lint as it passes by. Over time, this creates a dangerous blockage and a major fire hazard. The correct way is to use clamps to secure the joints and then seal them completely with high-temperature aluminum foil tape.

Understanding Maximum Vent Length

This is one of the most important rules, and it’s where a lot of DIY jobs go wrong. We're talking about the maximum length of your vent run. And no, it’s not just a simple measurement from your dryer to the outside wall.

Most codes set the maximum developed length at 35 feet. But here’s the catch: you have to subtract length for every single bend in the duct. The standard deductions are pretty straightforward:

- 5 feet for every 90-degree elbow

- 2.5 feet for every 45-degree elbow

So, a short-looking route with two 90-degree turns actually has a maximum straight run of just 25 feet (35 – 5 – 5 = 25). It’s a detail inspectors will absolutely look for, as it's directly tied to fire safety.

A simple installation on the main floor that punches straight through the wall is easy—it might only be three feet long. But a setup from a second-floor laundry room that has to snake down a wall and run across the basement ceiling can easily go over the limit once you factor in the elbows. In those cases, you’d need to rethink the route or look into a booster fan.

Following these rules is critical. It guarantees your dryer can do its job properly, pushing all that hot, damp air and lint safely outside, which protects your home and keeps your appliance running efficiently.

Deciding Between DIY and Hiring a Pro

So, should you tackle this dryer vent installation yourself or call in a pro? The answer really boils down to three things: the complexity of the job, your budget, and your own confidence level. A straight shot through an exterior wall can be a really satisfying and wallet-friendly DIY win. But once the route gets tricky, you'll want an expert's touch to keep things safe and up to code.

For a lot of homeowners, the biggest draw for DIY is saving money. When you do the work yourself, you're only on the hook for materials, which can be surprisingly affordable for a standard job.

Budgeting for a DIY Installation

If you're looking at a simple, straight run out an exterior wall, your shopping list won't be too long. Here's what you can generally expect to spend on materials:

- Rigid Metal Ducting: A standard 8-foot section will probably set you back $15-$25.

- Exterior Vent Cap: For a decent cap with a pest guard, plan on $20-$30.

- Elbows and Clamps: Grab a couple of adjustable elbows and some worm-gear clamps for another $15-$20.

- Sealing and Tools: Aluminum foil tape and a good hole saw bit could be $30-$50, though you might already have some of these tools kicking around.

All in, you can often get a basic DIY dryer vent installation done for under $100, assuming you've already got a drill and stud finder. That makes it a pretty tempting option for straightforward venting paths.

Choosing the DIY route for a simple project is a great way to save money and gain valuable home improvement experience. The key is to be honest about the project's scope and your own skill level before you start cutting holes.

When to Bring in a Professional

While going it alone is great for simple jobs, some situations really call for a professional. A pro brings years of experience, specialized equipment, and crucial knowledge of local building codes to the table, making sure the job is done right the first time.

The cost for a professional install can vary quite a bit depending on how complicated things get. You might see a range anywhere from $140 to $600. A simple 8-foot run could be on the lower end, around $110, while a more involved 20-foot installation might be closer to $210. The price climbs if they need to cut through tough materials like brick or concrete.

It’s probably time to call in an expert if your installation involves any of the following:

- Long or Winding Routes: If the total vent length is pushing past 35 feet (once you factor in the elbows), you might need a booster fan. That’s a job best left to the pros.

- Tough Materials: Punching through brick, concrete, or thick stucco isn't easy. It takes special tools and know-how to do it without damaging your home's structure.

- Roof or Soffit Venting: Terminating a vent through the roof is a whole different ball game. It needs proper flashing to prevent leaks and often requires special vent caps to stop lint from building up and causing problems.

- Just Not Feeling It: If you're nervous about hitting hidden wiring, navigating around plumbing, or making sure you're meeting code, hiring a pro is worth the peace of mind.

Ultimately, a professional ensures the work is safe, efficient, and compliant. If your project has any of these red flags, investing in an experienced air duct cleaning company that also handles installations is easily the smartest and safest call.

Common Dryer Vent Installation Questions

Even after you've done all your homework, a few questions always seem to pop up. When you're dealing with something as important as a dryer vent installation, you want to be completely sure you've got it right. Let's run through some of the most common things we get asked by homeowners here in the GTA.

Think of this as your final check-in for peace of mind, clearing up those last-minute "what ifs" before you hit 'start' on that first load of laundry.

Can I Use Flexible Foil Ducting for My Dryer Vent?

Let's be blunt: absolutely not. We see this a lot, and it's a major safety issue. Building codes and fire safety standards are crystal clear on this—you can't use those flimsy foil or vinyl ducts inside walls, ceilings, or floors. There's a very serious reason why.

The accordion-style ribs inside those flexible ducts are a perfect trap for lint. It builds up fast, creating a massive fire hazard. They also get crushed easily behind the dryer, which cuts off airflow and forces the machine to overheat. For a safe and proper installation that will pass inspection, you must use smooth, rigid metal ducting.

What Is the Maximum Allowed Length for a Dryer Vent?

This is a critical detail that trips up a lot of DIYers. Most building codes and appliance manuals set the maximum vent length at 35 feet. But it’s not as simple as measuring a straight line from your dryer to the outside wall.

Every single turn in the duct reduces that maximum allowable length. The math is pretty straightforward:

- Subtract 5 feet for every 90-degree elbow.

- Subtract 2.5 feet for every 45-degree elbow.

So, if your route has two 90-degree elbows, your total duct run can't be more than 25 feet long (35 – 5 – 5 = 25). Following this rule is non-negotiable for keeping the air moving properly and preventing lint from building up—the number one cause of dryer fires.

What Is the Best Way to Vent a Centrally Located Dryer?

What happens when your laundry room is stuck in the middle of the house, far from an exterior wall? This is where things get tricky. The most common solutions are to vent straight up through the roof or run the ductwork horizontally through a crawlspace or basement. The goal is always the same: find the shortest, most direct path outside.

A roof vent can work, but it comes with its own set of headaches. It has to be flashed perfectly to prevent leaks, and the vent caps are notorious for getting clogged with lint. Climbing on your roof to clean it out is not just a pain—it's dangerous. For these more complex runs, it’s always best to bring in a professional.

If you do vent through the roof, make sure a proper terminal is used. A standard bathroom fan vent will clog in no time. You need a high-quality roof vent terminal with a larger opening and a damper that won't restrict lint from passing through.

How Often Should I Clean My Dryer Vent?

Getting your new vent installed is step one; keeping it clean is the long-term commitment. As a general rule, you should have your dryer vent professionally inspected and cleaned at least once a year.

However, if you've got a busy household, do laundry nearly every day, own shedding pets, or have a longer vent with a few elbows, you should probably clean it every six months. The biggest red flag? When your clothes are still damp after a full cycle. For a complete breakdown, check out our guide on how often dryer vents should be cleaned to keep your home safe.

At Can Do Duct Cleaning, we're experts in professional dryer vent installations and cleaning services across the GTA. We make sure every job is safe, efficient, and up to code. Protect your home and family by booking an inspection with our experienced technicians today at https://www.candoductcleaning.com.