When your central vacuum starts acting up, the first rule is simple: don't panic. More often than not, the culprit is something straightforward that you can fix yourself in under an hour. Issues like weak suction or a system that won’t turn on are usually caused by a full canister, a hidden clog, or a tripped breaker.

Quickly Diagnosing Central Vacuum Problems

Before you grab tools and start taking things apart, a little detective work will save you a ton of time and frustration. A central vacuum isn't a complicated machine, and its problems tend to be predictable. Nailing the diagnosis right from the start is your ticket to a quick fix.

So, where do you begin? Start with the symptoms. Is the unit completely dead, or is the motor running but not pulling any air? Does the problem happen at every single inlet valve around the house, or is it isolated to just one? Answering these questions immediately narrows down the possibilities.

This simple diagnostic check helps you sidestep common mistakes. For instance, there’s no point hunting for a clog deep in the pipes if the real issue is just a full dustbin choking off the airflow. Likewise, if the motor works when you switch it on manually but not from the hose, you know the problem is likely in the low-voltage wiring.

Understanding the Troubleshooting Flow

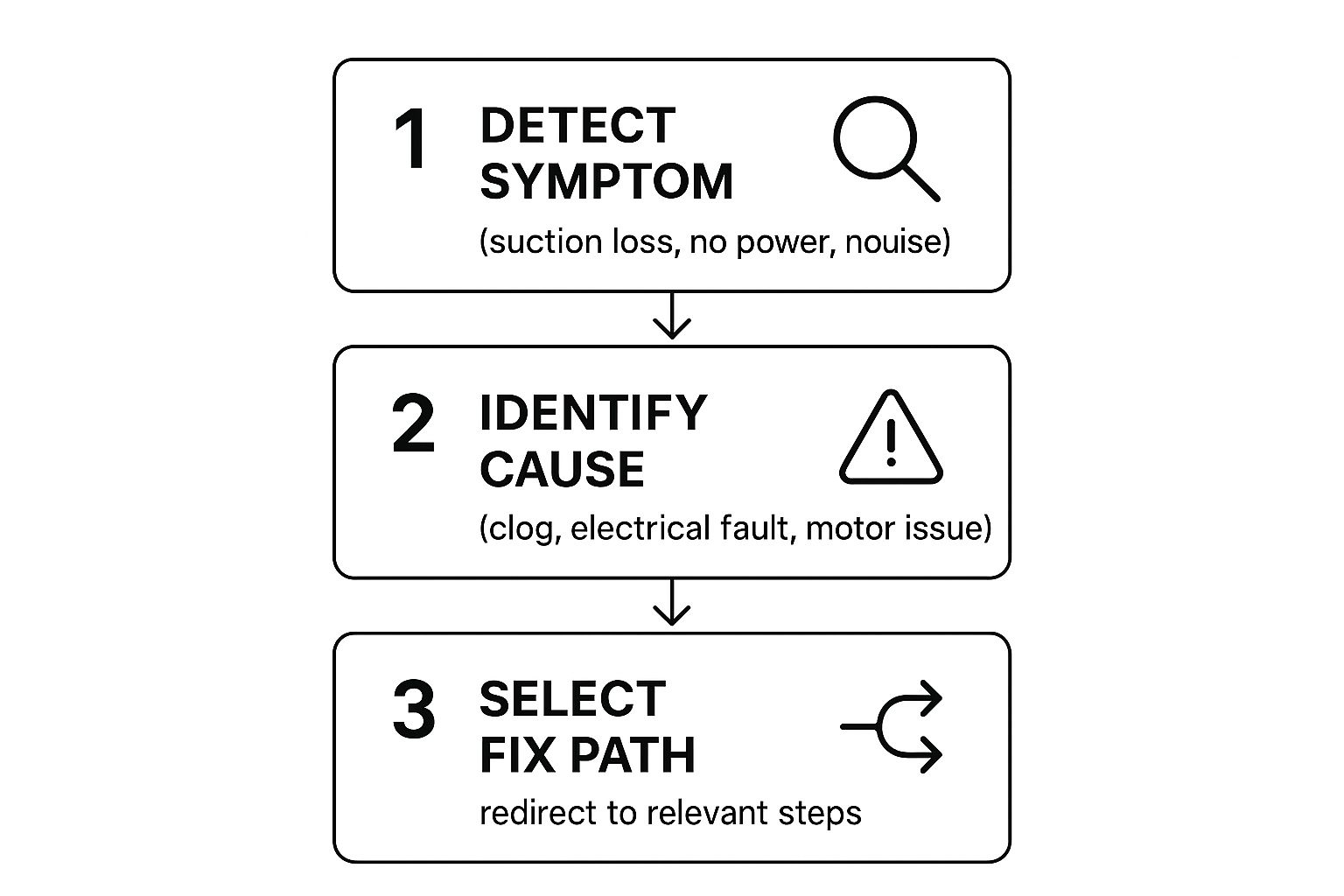

Think of troubleshooting as a simple three-step dance: identify the symptom, isolate the cause, and then follow the right solution path. This logical approach works every time.

This infographic breaks down the basic diagnostic workflow, guiding you from the initial problem to the final fix.

As you can see, a logical progression is the most efficient way to tackle any central vacuum repair.

To help you get started even faster, we've put together a quick reference table. Just find your symptom in the first column to see the most common cause and where to find the solution.

Central Vacuum Symptom and Cause Quick Guide

| Symptom | Most Likely Cause | Jump to Section |

|---|---|---|

| Weak Suction | Full canister, clogged filter, or a clog in the hose/pipes. | Fixing Low Suction |

| No Power | Tripped circuit breaker, GFCI, or internal unit fuse/breaker. | System Won't Turn On |

| Motor Runs But Won't Shut Off | Faulty relay or short in the low-voltage wiring. | Motor Won't Stop Running |

| Strange Noises (Grinding, Whining) | Worn motor bearings or debris in the motor fan. | Dealing with Strange Noises |

| Burning Smell | Overheating motor due to a blockage or motor failure. | Dealing with Strange Noises |

This table should help you pinpoint the issue and jump straight to the relevant troubleshooting steps in this guide.

Common Symptoms and Their Usual Suspects

Most central vacuum headaches come from one of three places: an airflow blockage, an electrical fault, or a motor issue at the main power unit. Knowing how does a central vacuum system work can give you a big-picture view that makes diagnosis much easier.

Here’s a quick rundown of the most common complaints we see:

- Weak or No Suction: This is, by far, the most frequent issue. 9 times out of 10, it’s an airflow problem. The usual suspects are a full collection canister, a caked-on filter, an air leak somewhere in the hose or its connections, or a clog lodged in the hose, wand, or pipes.

- System Won't Turn On: If you plug in the hose and get nothing, it's almost certainly an electrical issue. The first stop is always your home's main circuit breaker panel. After that, check the reset button on the power unit itself. If both are fine, the problem could be with the low-voltage wiring running to the inlets or a faulty switch in the hose handle.

- Strange Noises or Burning Smell: This is serious. Any grinding sounds, high-pitched whines, or a distinct burning odour are major red flags pointing straight at the motor. These symptoms often mean the motor bearings are shot or it’s overheating badly. Shut the unit off immediately to prevent further damage.

Solving Weak Suction and Airflow Issues

It's one of the most common—and annoying—central vac problems: you plug in the hose, start cleaning, and realize it's just not picking things up like it used to. That weak suction is a real pain, but the good news is that it’s usually an easy fix.

Before you jump to conclusions and assume there's a major clog deep inside your walls, take a breath. Most suction issues are caused by simple things you can check yourself, either at the hose you're holding or at the main unit. Let's walk through it logically, starting with the most common culprits.

Start Where The Cleaning Happens

Your first stop should always be the equipment you use every time you vacuum. The hose, wand, and powerhead are the prime suspects for blockages and air leaks that kill your suction power.

- Look through the hose and wand. Pull the hose out of the wall inlet and check both ends for anything obvious stuck inside. A neat trick I use is to drop a coin or a marble into one end; if it doesn't pop out the other side, you've found your clog.

- Inspect the powerhead. Flip it over and look at the brush roll. Hair, string, and carpet fibres are notorious for wrapping around it so tightly that air can barely get through. Clear all that gunk out and make sure the brush can spin without a fight.

- Feel for air leaks. Even a tiny crack in the hose handle or a bad seal where the wand connects can cause a massive drop in suction. To find it, plug the hose in, turn the system on, and cover the end of the wand with your hand. Run your other hand along the entire hose, especially near the handle and cuffs, listening and feeling for a tell-tale hissing sound.

Move To The System's Core

If your cleaning tools get a clean bill of health, it’s time to head to the main power unit in your garage or basement. This is where the magic happens, and it's also where the biggest performance killer lives: the filter.

A full collection bin or a filter choked with fine dust can easily cut your vacuum's suction by over 50%. This is often the real reason behind a slow, gradual decline in performance that you might not even notice until it gets really bad.

Start by emptying the canister, even if it doesn't look completely full. Then, take a close look at the filter. It could be a screen, a cartridge, or a foam pad, depending on your model. You can often clean them with a brush or a good rinse, but always double-check your manual first.

If the filter is totally caked with dust and cleaning doesn't help, just replace it. You'd be amazed how often this one simple step makes a system feel brand new. Keeping that filter clean is a critical part of any good central vacuum system maintenance plan.

Investigate The Inlets And Piping

With the easy stuff out of the way, you can now check the system's infrastructure. The problem could be a leaky wall inlet or, less commonly, a clog somewhere in the pipes.

A worn-out gasket on an inlet valve is a sneaky source of suction loss. Pop open the inlet door and check the condition of the seal inside. If it's cracked, flat, or feels brittle, it’s not sealing properly when you plug the hose in.

To test the suction of the whole system and narrow down the problem, you'll need a helper for a quick "two-person test."

- One person stands by the main power unit.

- The other person goes to the inlet that's farthest from the unit.

- Turn the system on from that inlet. The person at the unit should feel strong suction from the intake port.

- Next, seal the distant inlet with the palm of your hand. The person at the unit should immediately hear the motor's sound change as airflow is cut off.

If the suction is great at the main unit but weak at the inlet, you've probably got an air leak somewhere in the pipe network. But if the suction is weak right at the power unit itself, the issue is likely with the motor or its internal seals. This is a key diagnostic step in any central vacuum troubleshooting.

Interestingly, industry data backs this up, showing that suction-related problems account for about 40% of all service calls. It's the number one issue homeowners face with these systems, far and away.

How to Locate and Remove Stubborn Clogs

So, you've checked the basics. The canister is empty, the filter is clean, and you’ve made sure the hose isn't the problem, but the suction is still seriously lacking. Time to roll up your sleeves and hunt for a more stubborn issue—a clog hidden somewhere deep in your home's pipe network. This is where the real detective work begins, but don't worry, I'll walk you through how to find and clear it like a pro.

The trick is to be methodical. You're going to find the clog by a simple process of elimination, working your way out from the main power unit. First, head to the inlet valve closest to your central vacuum unit. Plug in your hose and test the suction. If it’s strong, you're good. Now, move to the next closest inlet and repeat the test.

Keep going, inlet by inlet, moving further away from the main unit. Eventually, you'll find one with noticeably weaker suction. Bingo. The clog is trapped somewhere in the pipe between that weak inlet and the last one that had full power. This little test pinpoints the problem area without any guesswork.

Isolating The Blockage Location

Now that you've narrowed it down to a specific pipeline, you can start to zero in. In my experience, the culprit is usually something surprisingly large—a kid's toy, a stray sock, or a big clump of pet hair that finally gave up the ghost.

This diagram gives you a good idea of what the pipe network behind your walls looks like.

Understanding this layout helps you visualize where things can get stuck. Most blockages happen at a 90-degree elbow joint, where it's easy for debris to get snagged.

Safe and Effective Clog Removal Techniques

Okay, you know where the clog is. Now, let's get it out without causing any damage. Your main goal is to protect your PVC piping. Whatever you do, never pour chemical drain cleaners into the system. They can soften and warp the plastic pipes, turning a simple clog into an expensive, wall-opening repair job.

Instead, let's try a few proven methods that actually work.

- Harness Your Vacuum's Power: First, go around and seal all the other vacuum inlets in your house with duct tape. Now, plug your hose into the inlet that’s before the clog (closer to the motor). Block the end of the hose with your palm for a few seconds to build up pressure, then quickly release it. That sudden burst of suction is often enough to jolt the clog free.

- Reverse the Flow: A powerful shop vac can be a lifesaver here. Tightly seal its hose over the clogged inlet and switch it to blow air back toward the main unit. This reverse pressure can push the clog out the way it came in.

- Bring in a Clearing Tool: If pressure tricks don't work, it's time for a more direct approach. A specialized central vacuum clearing cloth or a flexible plumber's bladder can do wonders. These are designed to be safely sucked through the pipes to physically push the obstruction out. Looking into different central vacuum accessories might introduce you to a tool made exactly for this situation.

A Few Pro Clog-Busting Tips

Sometimes, a clog just doesn't want to budge. If the basics aren't cutting it, you might need to get a little more creative.

One of the biggest mistakes I see homeowners make is grabbing a metal plumber's snake. Its sharp edges will gouge, crack, or even puncture the PVC pipes. You'll clear the clog but create hidden leaks in your walls—a true nightmare to find and fix. Stick to tools made for vacuum systems.

Here are a couple of other tactics to try:

- The "Push-Pull" Method: This one can be really effective. Alternate between using your central vacuum's suction on one side of the clog and the shop vac's blower on the other. This back-and-forth pressure can wiggle even the most stubborn blockage free.

- The "Cotton Ball" Trick: For smaller, partial clogs, try this old-school trick. From an inlet farther away than the clog, suck a few cotton balls or a special cleaning cloth into the system. They act like a small plunger, building up pressure behind them to push the blockage through.

- Check the Main Line First: Before you get too deep, it's worth checking the pipe right where it enters the power unit. Debris loves to accumulate at this final bend. Just turn the power off, disconnect that section of pipe, and take a quick look inside. You might find the problem is right there.

Troubleshooting Electrical and Power Unit Failures

So, you plug in your hose, flip the switch, and… nothing. Just silence. When your central vac is completely dead, you can usually rule out a clog and start thinking about the power supply. Electrical problems can sound scary, but a lot of the time, the fix is surprisingly simple.

Before you start worrying about a burnt-out motor, let’s run through the basics. It’s almost always the simple stuff that trips us up.

Initial Power Checks The First Steps

First things first, walk over to your home's electrical panel. A central vac motor is a beefy appliance, and it’s not uncommon for it to trip a breaker, especially when it first kicks on. Scan the panel for any breaker that's flipped to the "OFF" position or is stuck in the middle.

If you flip it back on and it immediately trips again, unplug the main power unit from the wall and give a professional a call. That’s a sign of a more serious short circuit you don’t want to mess with. If electrical issues are becoming a theme in your home, understanding the basics, like how to replace a fuse box, can give you some valuable context.

Next, check the power unit itself. Most models have a small reset button built right in—usually red or black. Give it a firm press. If you feel a click, that was likely the problem. This is just the unit's own little safety feature, which can trip from a brief power surge or from overheating.

Diagnosing The Low-Voltage Circuit

Okay, so the breaker is fine and the reset button didn’t do the trick. Now we can look at the low-voltage control wire. This is the thin wire running from all your wall inlets back to the power unit; it’s the messenger that tells the motor to turn on. A break somewhere along this line is a classic point of failure.

You can run a quick bypass test to see if the motor is even getting the message. Make sure the unit is plugged in but turned off, then find the two low-voltage contact screws on the side of the main unit. Carefully use a small piece of wire (a paperclip works in a pinch) to create a bridge between them for just a second.

If the motor roars to life when you bridge those contacts, you’ve got good news! The motor is fine. The problem is somewhere in the low-voltage wiring running through your walls, not in the expensive power unit itself.

This little trick saves a ton of diagnostic time and points you in the right direction.

Recognizing Signs Of Motor Failure

Sometimes, the problem really is the heart of the system—the motor. A dying motor will almost always give you some warning signs before it quits for good. If you learn what to listen and smell for, you can get ahead of the problem.

Here are the tell-tale signs of a motor on its last legs:

- Loud Grinding or Squealing: A high-pitched squeal or a deep, gravelly grinding noise is a dead giveaway that the motor’s internal bearings are shot.

- A Distinct Burning Smell: This is a big one. An acrid, electrical burning odour means the motor is seriously overheating. Shut the power off at the breaker immediately.

- Intermittent Power: Does the motor start and stop randomly while you’re vacuuming? Or maybe it struggles to get going? The motor brushes, which are designed to wear down over time, are likely the culprits.

Tackling a motor or power unit failure is a common part of long-term ownership. Considering a brand-new installation can cost anywhere from $1,094 to $2,194, most homeowners would much rather repair their system, especially since all the piping is already in the walls. You can find more helpful info right here in our detailed guide on how to properly take care of your home central vacuums.

Stay Ahead of Problems with a Proactive Maintenance Plan

Honestly, the best central vacuum troubleshooting guide is the one you never have to open. Knowing how to fix problems is great, but preventing them in the first place is what really saves you time, money, and headaches.

A simple, consistent maintenance routine is your strongest defence against clogs, suction loss, and motor burnout. Think of it like changing the oil in your car—a few minutes of effort every few months keeps the whole system running like a dream for years to come.

Your Quarterly System Checkup

Consistency is everything. You don't need to block off your whole Saturday, but a quick inspection every three or four months can stop small issues from turning into expensive repairs. This is your chance to get ahead of the most common culprits.

Here’s what I recommend checking:

- Empty the Canister: Don't let it get stuffed to the brim. When the bin is too full, it chokes off the airflow, putting a major strain on the motor and killing your suction power.

- Inspect the Filter: This is a non-negotiable step. Whether you have a foam, cartridge, or cloth filter, give it a good look. If it's caked with dust, clean it. If it looks worn out or just won't come clean, it's time for a new one.

- Check Your Hose and Tools: Give the hose a quick scan for any cracks or splits, especially at the cuffs where they get the most wear. While you're at it, flip over your powerhead and pull out any hair or string wrapped around the beater bar—that stuff is a vacuum's worst enemy.

The Annual Deep-Dive for Motor Health

Once a year, it pays to spend a little more time with the heart of your system: the main power unit. This annual check helps ensure the motor is happy and your pipes are clear.

Here's a handy trick I've used for years: grab a special pipe-cleaning cloth and suck it through the system from your farthest inlet. As it travels through the network, it scours away the fine dust that builds up on the pipe walls over time, preventing the slow, gradual buildup that leads to stubborn clogs.

Pro Tip: While you're near the power unit, just listen. Does the motor sound smooth? Any new grinding, high-pitched whining, or rattling noises are red flags. These are often the first signs that motor bearings or brushes are on their way out, and catching it early is always better than a complete failure.

Taking care of your central vac is a key part of overall home upkeep. For those new to homeownership, getting a handle on the bigger picture is crucial, and these essential home maintenance tips for new homeowners are a fantastic starting point.

Your Central Vacuum Maintenance Checklist

To make things even easier, here’s a simple schedule you can follow. Sticking to this will prevent the most common problems and add years to the life of your entire system.

| Maintenance Task | How Often | Why It Matters |

|---|---|---|

| Empty Collection Canister | Every 1-2 months (or when 3/4 full) | Prevents motor strain and suction loss. |

| Clean or Replace Filter | Every 3-6 months | Ensures maximum airflow and protects the motor from dust. |

| Inspect Hoses & Attachments | Every 3-4 months | Catches cracks, leaks, and blockages early. |

| Clean Powerhead Beater Bar | As needed (check monthly) | Removes tangled hair/string that restricts airflow. |

| Check Motor Brushes | Annually | Catches wear and tear before it leads to motor failure. |

| Clean In-Wall Piping | Annually (using cleaning cloths) | Removes fine dust buildup and prevents future clogs. |

Following this simple checklist makes maintenance a breeze and keeps your system performing at its best.

The Power of Prevention

It might feel like just another chore, but sticking to a maintenance schedule has a huge payoff. We see it in repair data all the time. A troubleshooting guide based on regional repair statistics shows that simple preventative steps—like regular hose checks, replacing filters every 6 to 12 months, and making sure electrical connections are tight—can reduce emergency repair calls by nearly 30%.

Ultimately, this isn't just about avoiding a service call. It’s about protecting the investment you made in your home. A well-maintained system cleans better, runs more efficiently, and will give you years of reliable, powerful performance.

Common Questions About Central Vacuum Repair

Even the best guides can't cover every single quirky problem that might pop up. Sometimes, the issue you're facing doesn't neatly fit into a box labelled "clog" or "bad motor." Let's dive into some of the questions we hear all the time from homeowners trying to get to the bottom of their central vac troubles.

Can I Use a Plumber's Snake to Clear a Clog?

I get this question constantly, and my answer is always a hard no. It seems logical, I know, but a metal plumber's snake is the absolute last thing you want to put inside your central vacuum piping.

Those snakes are built tough for clearing out metal drain pipes. Your vacuum lines, on the other hand, are made of a much softer PVC. Shoving a rigid, sharp-edged metal snake through them is a surefire way to scratch, gouge, or even puncture the pipe wall. The real kicker? You might not even realize you've damaged it. A tiny puncture behind a wall creates a slow, silent air leak that absolutely kills your suction, leaving you with a nightmare of a repair job.

Stick to tools made for the job. A flexible clearing hose or specially designed cleaning cloths can bust through most blockages without tearing up your pipes.

What Do Strange Noises From the Motor Mean?

Think of your central vacuum's motor as a pretty good communicator—if you know how to listen. Those strange sounds are its way of telling you something is wrong, and ignoring them will only lead to a bigger, more expensive headache.

- A high-pitched whistle? That’s almost always an air leak or a filter that's completely choked with dust. The motor is starving for air and is straining to pull it through a tiny opening, creating that distinct sound.

- A deep, loud rumbling or a metallic grinding? That’s bad news. It points directly to failing motor bearings. This is a serious problem that needs immediate attention. If you keep running it, you risk the motor seizing completely.

- A muffled, tired sound? If the motor sounds like it's struggling and you've got weak suction, you've got a classic clog somewhere in the system.

How Can I Tell if My Hose Is Leaking or Clogged?

Your hose is the workhorse of the system, and it's often the first place to look when suction drops. Luckily, figuring out if it's clogged or leaking is a quick, one-minute diagnosis.

First, check for a clog. Unplug the hose from the wall inlet. Hold it straight up and down and drop something small and heavy, like a coin or a battery, into the top. If it doesn't pop out the other end, you've found your blockage.

To check for a leak, plug the hose back into the inlet and turn the system on. Seal the other end of the hose tightly with the palm of your hand. Now, run your other hand slowly along the entire length of the hose, listening and feeling for escaping air. A hissing sound is a dead giveaway. Pay close attention to the cuffs on both ends—they're the most common spots for splits and cracks.

A tiny, one-inch split in a central vacuum hose can slash the suction power at the cleaning head by a shocking 20-25%. It's a small problem with a massive impact.

Is It Worth Repairing an Older Central Vacuum Motor?

This one really boils down to simple economics: how old is your unit, and how much will the repair cost?

If your system is less than 10 years old, a repair is almost always the smart choice. Swapping out motor brushes or a faulty relay is far cheaper than replacing the whole unit. For many families, especially those with allergies, keeping the system running is non-negotiable—a powerful vacuum is one of the best ways to get rid of pesky pet dander.

Once your unit crosses that decade-old mark, the decision gets tougher. If you're looking at a repair bill that’s more than half the price of a brand-new power unit, it's probably time to replace it. A new unit won't just be more powerful and energy-efficient; it'll also come with a fresh warranty, giving you years of worry-free cleaning.

When a simple fix turns into a major project, or you'd just rather have an expert handle it, Can Do Duct Cleaning is here to help. Our technicians have seen it all and can get your central vacuum running like new again. For professional service you can count on, visit us at https://www.candoductcleaning.com.